Optimization of the energy consumption of infrastructures and machines

Monitor energy consumption. Detect energy saving opportunities. Alert of consumption peaks.

Predictive maintenance

Detect anomalies preventively, anticipate breakdowns, reduce unscheduled downtime and improve production quality.

Optimizing Production Processes

Simulate and evaluate multiple optimization scenarios to help make decisions. Choose to execute or ignore recommendations, or automate repetitive tasks.

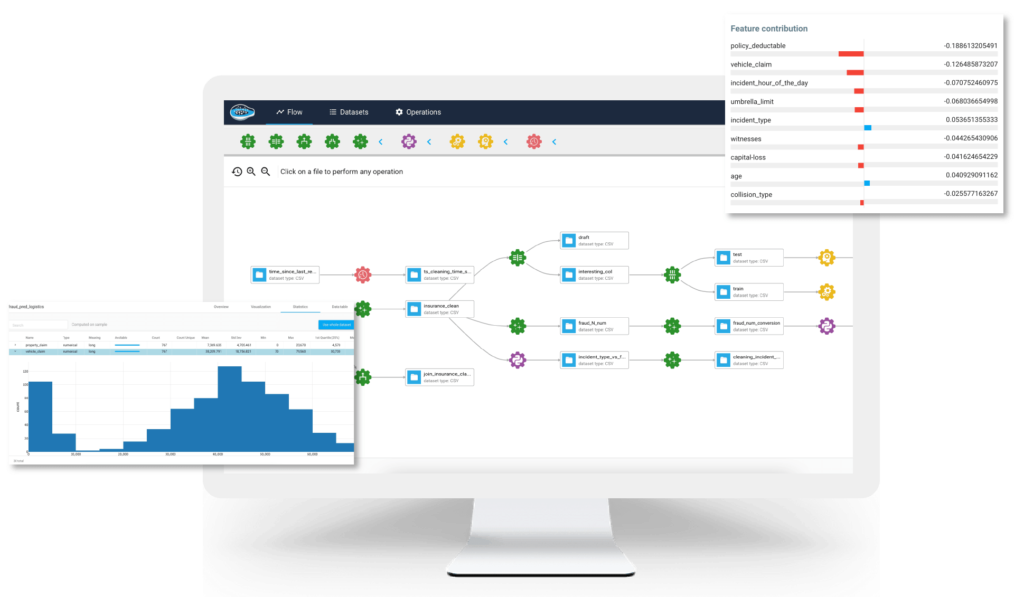

papAI, the AI platform that anticipates maintenance needs and prevents production shortage

The papAI platform enables companies to achieve their ambitions around industry 4.0.

and to meet their strategic challenges in predictive maintenance

Build each step of the Machine Learning models and propose the best areas of improvement to reinforce decision making.

Support you in predicting machine breakdowns and prioritising your repair actions.

Get transparency on the result obtained thanks to the interpretability

From Monitoring to Predictive Maintenance

Increased equipment availability and reduced unplanned downtime

Improved production quality through increased equipment reliability

Extended equipment life

Reduced equipment failure rate

Better management of spare parts stocks

Reduced maintenance costs

Benefits of the papAI platform

on predictive maintenance

Data collection and analysis to anticipate the defects and provide advanced interpretability to act accordingly, with objectives of driving maintenance operations at the right time: not too early to reduce costs, not too late to prevent breakdowns and production shortage.

Associated use cases

Anomaly Detection

Artificial intelligence automatically detects and prioritizes problems. In the manufacturing sector, detect anomalies preventively, anticipate breakdowns, reduce unscheduled downtime and improve production quality.