Scaling RAG Systems in Financial Organizations Artificial intelligence has emerged...

Read MoreHow Agentic AI Optimizes Manufacturing Workflows

Table of Contents

ToggleAgentic AI has emerged as one of the leading AI layers, built upon the foundation of powerful AI models like Llama, DeepSeek, and Mistral, and its impact now extends across a wide range of industries, including manufacturing.

Agentic AI is swiftly emerging as a crucial component for companies aiming for rapid expansion, thanks to its ability to independently drive smart automation, greatly boost operational efficiency, and streamline intricate workflows for maximum productivity

AI in the manufacturing market is poised for significant growth, with projections indicating it will reach $8.57 billion by 2025, a substantial increase from $5.94 billion in 2024. This remarkable expansion reflects an impressive Compound Annual Growth Rate (CAGR) of 44.2%.(source:allaboutai.com)

Find out how papAI can improve the deployment of AI projects in the Manufacturing Industry.

In this article, we will explain Agentic AI. We will look at its role in manufacturing. We will also highlight the real benefits it provides.

What does Agentic AI mean?

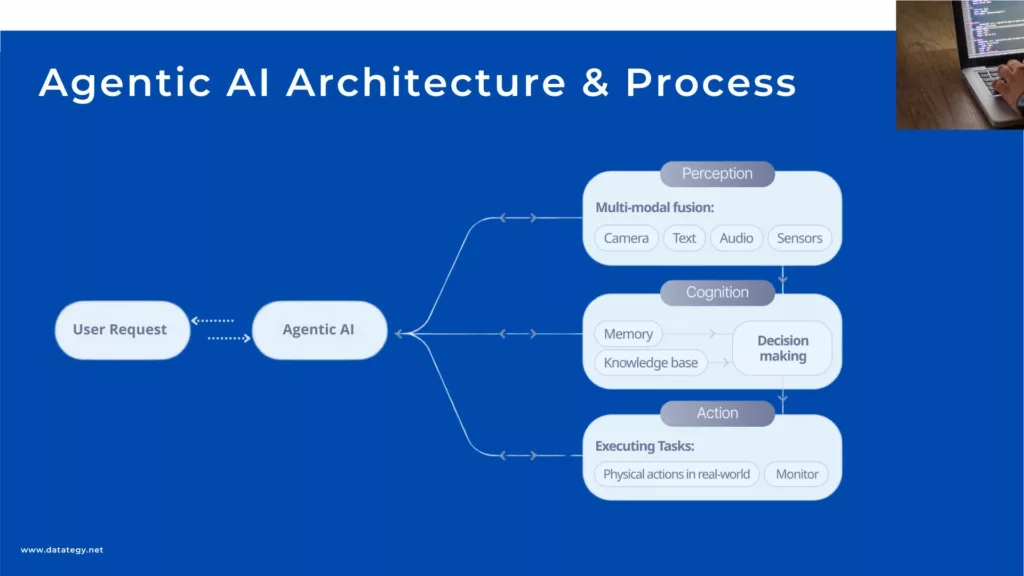

Agentic AI is a major advancement in artificial intelligence that goes beyond simple task execution to autonomous, goal-driven operation.

Imagine AI that does more than just follow commands; instead, it actively perceives its environment, makes decisions about complex situations, and then acts independently to accomplish predetermined goals. This combines perception, planning, and execution, enabling these AI agents to adapt and learn as they navigate dynamic environments. Unlike traditional AI, which usually requires explicit instructions,

Agentic AI is made to operate with a greater degree of independence, which makes it especially useful for solving complex, real-world problems that call for initiative and adaptability.

Which Types of Agentic AI exist?

Based on their unique characteristics and purposes, we have distinguished many categories of agentic AI:

Basic Reflex Agents:

- Function according to “condition-action” rules.

- Without taking into account past events or potential consequences, respond directly to current environmental inputs.

- Perfect for basic sensor-driven operations and other repetitive, simple tasks that need quick responses.

Reflex Agents Based on Models:

- Create a model of the world to monitor environmental elements that cannot be seen.

- Make better decisions by using this model, which will enable you to deal with changing circumstances more effectively.

- Ideal for applications where tasks are still quite simple but context is crucial.

Goal-Based Agents:

- Strive to accomplish particular objectives, allowing them to make plans that go beyond quick fixes.

- Determine whether various courses of action or pathways bring you closer to the intended result.

- Helpful in situations like route optimization where the agent needs to aim for a specific outcome.

Utility-Based Agents:

- Maximize a utility function that reflects performance or satisfaction in order to make more informed decisions.

- Able to select actions that provide the greatest value or benefit by weighing various outcomes.

- Perfect for complicated decisions, particularly those involving trade-offs, such as resource allocation.

Learning Agents:

- Continuously enhance their performance by taking lessons from previous decisions and results.

- Utilise methods like machine learning to gradually modify and improve your decision-making.

- Advantageous in dynamic settings with shifting conditions, such as logistics demand forecasting.

Multi-Agent Systems (MAS):

- Consists of several agents operating in the same environment, either cooperatively or competitively.

- Can work better as a team than as a solo agent at delegating, negotiating, and problem-solving.

- Frequently utilized in distributed systems, such as supply chain management networks.

Hierarchical Agents:

- Layered structure with higher-level agents supervising and directing lower-level agents.

- Give complex systems structure so that the actions of each agent are in line with the overall objectives.

- Efficient in complex, large-scale settings such as automated warehouse operations

Agentic AI Architecture & Process

What are the Advantages of Agentic AI in Manufacturing Industry

For Technical Professionals:

Enhance Decision-Making

The flexibility of traditional automation systems is limited by their adherence to preset rules. However, agentic AI functions more independently, evaluating facts in real time to generate wise choices without continual human intervention.

This implies that production lines may adapt dynamically to changes in demand, shortages of materials, or inefficiencies in machinery in the industrial sector. To maintain maximum efficiency without stopping operations, an AI system can, for instance, redirect work or modify schedules if it notices an unforeseen delay in one step of the process.

Better Adaptation in Real-World Task

Agentic AI continually improves its algorithms based on real-time and historical data, in contrast to static automation systems that need to be manually reprogrammed. This capability enables it to spot tiny inefficiencies, spot new trends, and make proactive operational adjustments.

For example, without human assistance, AI in an automobile factory may identify changes in defect rates, identify the underlying causes, and suggest process improvements to uphold quality requirements.

Effective Process Optimization

The capacity of agentic AI to streamline complicated procedures across several manufacturing lines is one of its most potent benefits. AI-driven agents assess a variety of factors, including machine performance, worker productivity, and material availability,

in order to recommend process enhancements. These systems ensure continual optimization at scale by streamlining production and dynamically adapting to unforeseen disturbances.

For Business Experts:

Increased Efficiency in Operations

Manufacturing companies are always looking for methods to save expenses and increase efficiency. Agentic AI improves quality control, reduces manufacturing delays, and automates repetitive operations.

Businesses may boost throughput, cut waste, and guarantee more seamless operations with fewer interruptions by putting AI-driven optimisations into practice. These improvements all help to boost productivity and profitability.

Making Decisions Based on Data

Accurate, real-time insights are necessary for making well-informed business decisions. Leaders are provided with actionable insight by agentic AI, which analyses enormous volumes of data from supply chains, manufacturing lines, and market trends.

Executives may more efficiently deploy resources, make better strategic decisions, and spot inefficiencies before they become expensive by using AI-generated reports.

Boosting ROI and Cutting Costs

The potential for cost reduction is among the most obvious advantages of agentic AI. AI dramatically reduces operating costs by automating labor-intensive jobs, optimizing energy use, and avoiding expensive downtime.

These savings might be reinvested by businesses in infrastructure, workforce development, or innovation. By increasing productivity and cutting expenses, AI-driven automation eventually raises return on investment (ROI).

The common advantage of using Agentic AI for technicians and business experts is to have a co-brain, a co-thinker, a collaborator who gives them constant support in their daily lives.

Thibaud Ishacian

Head of Product at Datategy

What are the Top Use cases of Agentic AI in Manufacturing

There are several advantages for using Agentic AI in your organization:

Real-Time Production Monitoring and Adjustments

AI-Powered Sensors for Dynamic Data Collection

Agentic AI interacts with its surroundings and takes proactive actions in response to real-time inputs, in contrast to traditional AI systems that passively gather and analyse data. Machine sensors continually provide data to the AI agent in manufacturing; however, rather than just storing the data for later study, Agentic AI understands it in real time and makes decisions on its own.

For instance, temperature-sensitive medication formulations in a pharmaceutical production plant need exact environmental control. In addition to monitoring temperature variations, agentic AI can also automatically change ventilation settings, cool systems, and even anticipate possible hazards, guaranteeing that production conditions stay ideal without the need for human intervention.

Agentic AI for Automated Anomaly Detection and Corrective Actions

By autonomously reacting to difficulties in real-time, agentic AI goes beyond traditional AI’s ability to recognise anomalies based on past trends. It actively resolves issues rather than merely pointing them out.

For example, typical AI may notify maintenance crews in an automobile assembly line if a robotic arm exhibits erratic motions as a result of mechanical wear. Conversely, agentic AI prevents downtime entirely by taking remedial action right away, such as assigning duties to other robots, rearranging processes, or modifying torque levels. This self-correcting feature guarantees smooth manufacturing and reduces the need for human involvement.

Furthermore, Agentic AI improves its decision-making for upcoming occurrences by continually learning from these anomalies.

Agentic AI for Dynamic Workflow Adjustments Based on Demand Fluctuations

The capacity of agentic AI in production to make real-time modifications based on changing demand without requiring human input is one of its most potent features. Though it still depends on operators to make adjustments, traditional AI is capable of predicting trends. However, as demand changes, agentic AI automatically modifies schedules, reallocates resources, and changes production priorities.

For instance, when an AI agent in an electronics manufacturing facility notices an unanticipated spike in demand for a particular chipset, it does more than just notify managers; it also increases production output on its own by redistributing labor, modifying machine cycles, and monitoring inventory flow in real time. Similarly, it proactively reduces output in the event of a decline in demand to prevent overstocking and needless expenses.

Predictive Maintenance and Downtime Reduction with Agentic AI

Agentic AI-Based Failure Prediction Using Historical Data

Conventional AI systems still depend on human operators to read reports and make choices, but they use previous data to forecast probable equipment faults. Conversely, agentic AI operates independently, continually observing current situations to improve its forecasts and learning from previous failures.

For instance, a traditional AI system may identify that a certain press machine at an auto parts production facility has a tendency to overheat after a predetermined number of cycles. But an agentic AI system goes one step further—it not only anticipates when the overheating will happen, but it also automatically modifies cooling systems and slows down particular operations.

Because of its ongoing capacity for self-learning, Agentic AI may modify its failure predictions in response to evolving operational circumstances, thereby improving the accuracy and efficacy of maintenance plans.

Proactive Maintenance Scheduling to Reduce Costs

Schedules for routine maintenance can result in needless service, which wastes time and money. On the other hand, waiting until a machine breaks down leads to expensive repairs and unplanned downtime. By dynamically scheduling maintenance based on real equipment status rather than set timetables, agentic AI removes these inefficiencies.

For example, at a food processing facility, Agentic AI tracks wear and tear in real time rather than doing scheduled maintenance on conveyor belts. It automatically plans maintenance during off-peak hours if it notices that a belt is failing more quickly than anticipated as a result of higher production demand, guaranteeing repairs are completed before failure with the least amount of disturbance.

Agentic AI for Automated Notifications of Possible Equipment Failures

When agentic AI recognises anomalies in predictive maintenance, it can take independent action. Agentic AI proactively sends automatic alerts and even initiates remedial actions before small problems turn into big failures, whereas ordinary AI could only provide reports and let technicians handle the rest.

For instance, if a rolling mill in a steel mill starts to exhibit odd vibration patterns, which might be a sign of a bearing failure, Agentic AI does more than simply record the abnormality. To prevent interruption, it instantly notifies maintenance personnel, recommends certain remedial measures, and, if required, modifies machine speed or transfers production duties to other pieces of machinery.

Furthermore, by integrating with inventory management and enterprise resource planning (ERP) systems, agentic AI can guarantee that replacement components are purchased in advance.

Supply Chain Optimization and Demand Forecasting with Agentic AI

Agentic AI for Demand Forecasting for Just-in-Time Production

Historically, manufacturers have relied on demand projections derived from historical patterns; however, these approaches frequently fall short in capturing abrupt changes in consumer behaviour, market dynamics, or outside disturbances. By continually evaluating real-time sales data, market trends, competitor actions, and even world events, agentic AI elevates forecasting to a new level and dynamically improves its forecasts.

Agentic AI takes direct action on its findings, in contrast to traditional AI, which generates reports for human decision-makers. For instance, Agentic AI may automatically modify production plans, rearrange raw materials, and distribute resources in a consumer electronics plant in response to an unforeseen spike in demand for wireless earbuds. This just-in-time production strategy avoids shortages and overstock by reducing extra inventory and guaranteeing that items are accessible when needed.

Self-governing Procurement and Supplier Selection

Procurement teams must assess vendors’ dependability, cost effectiveness, and delivery schedules as part of the manual and time-consuming supplier management process. By independently evaluating suppliers in real time and selecting the best choices based on variables like lead times, quality ratings, geopolitical risks, and market price, agentic AI revolutionises this.

In the automobile industry, for example, if a major component supplier is delayed, agentic AI does more than simply identify the problem; it actively looks for substitute suppliers, bargains for lower prices depending on market conditions, and places new orders. It guarantees that buying choices are in line with supply chain resilience and cost effectiveness, minimising bottlenecks without the need for human intervention.

Agentic AI for Evaluation of Supply Chain Disruption Risk

Natural disasters, abrupt changes in the market, and geopolitical conflicts may all cause disruptions to global supply networks. Agentic AI adopts a proactive approach to risk management, continually monitoring global news, weather patterns, economic indicators, and even social media sentiment to anticipate any disruptions before they happen. Traditional risk management depends on reactive tactics.

For instance, in order to reduce risk, Agentic AI in the pharmaceutical sector instantly assesses other sourcing alternatives, modifies inventory levels, and recalibrates production schedules if it discovers an imminent labor strike at a key supplier’s facility. In a similar vein, the AI automatically reroutes logistics to avoid delays if severe weather threatens a shipping route.

What is the Biggest Challenge in Agentic AI implementation within your Manufacturing Organizations?

There may be difficulties in implementing agentic AI in manufacturing, particularly with regard to training and staff adaption. Employees must adopt an attitude that embraces cutting-edge technology and abandons old manual procedures in order to use agentic AI systems, which function autonomously and make choices in real time.

To guarantee that workers feel at ease collaborating with AI-driven systems, this shift frequently necessitates significant workforce upskilling and reskilling. Beyond only teaching employees how to use AI tools, training should also emphasise developing a collaborative mindset so that staff members can successfully comprehend AI insights, step in when needed, and have faith in the AI’s judgement.

Datategy Magazine: AI Industrialization & Future Challenges

Datategy Magazine serves as your premier source for in-depth data insights, offering comprehensive coverage of the latest trends, strategies, and developments in the data industry. With a focus on AI industrialization and future challenges, we provide valuable analysis and expert commentary to help you stay ahead in this rapidly evolving landscape.

What are the Advantages to use papAI in Agentic AI deployment?

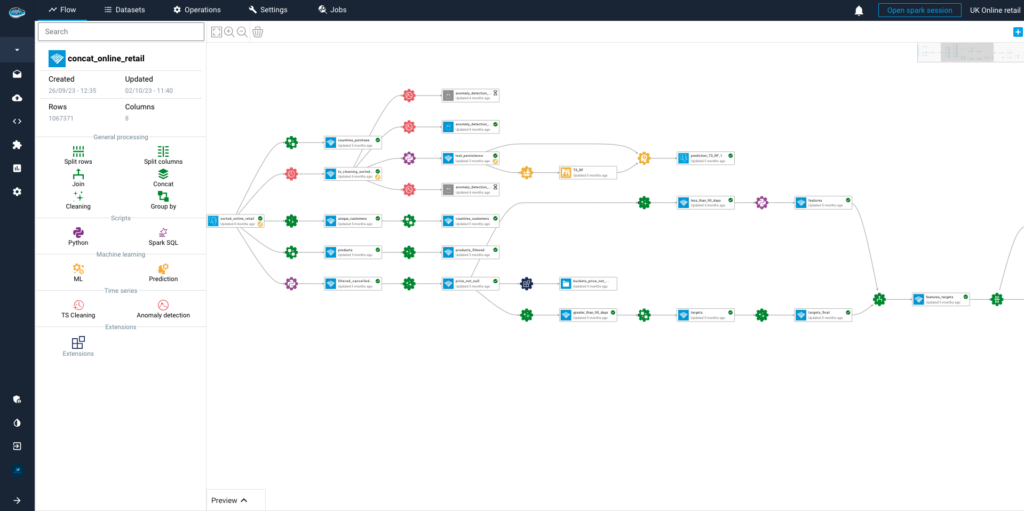

papAI is an all-in-one AI solution designed to streamline and optimize industry-specific operations through autonomous, real-time decision-making. It leverages multi-agent orchestration, contextual AI, and industrial-scale execution to deliver tailored solutions in areas like legal, finance, supply chain, and more.

With robust features for traceability, governance, and scalable deployment, papAI ensures compliance, security, and efficiency, making it ideal for businesses seeking to enhance performance while maintaining control over their AI processes.

Multi-Agent AI Orchestration in papAI

Businesses can use AI assistants designed for specific industries. These industries include banking, supply chain, and law. This is possible because of papAI’s ability to manage multiple agents.

These assistants operate independently, performing specialized duties like as data retrieval, information qualifying, transaction or document validation, and decision-making based on predetermined rules or dynamic inputs.

In legal contexts, for instance, an agent can independently extract pertinent case law, verify legal provisions, and provide suitable legal frameworks for a contract. Similar to this, an AI assistant in finance might evaluate market data, validate investment prospects, and provide suggestions in real time.

Real-Time Contextual AI

Using large language models (LLMs) supplemented by Retrieval-Augmented Generation (RAG), papAI guarantees that answers are based on current, sector-specific information.

This AI model stays accurate and relevant to current market conditions and legal rules. It does this by not only giving answers but also getting real-time data from trusted sources. papAI can help predict market trends in finance. It can also identify regulatory needs in healthcare. To do this, it uses specialized external resources. This helps it provide precise answers.

Additionally, these answers may be explained, giving companies confidence in the AI’s judgment. In regulated businesses where decision responsibility is essential, this degree of openness is essential.

+ Industrial-Scale AI Execution

Managing multiple agent tasks at the same time across many cases is one of papAI’s unique features. This helps businesses grow while keeping efficiency high.

papAI easily adapts to the needs of different industries. It can handle many customer support inquiries or manage supply chain logistics in real time. The system can change its models for a specific industry without needing complete retraining. This reduces downtime and ensures the AI meets the changing demands of busy environments.

Businesses may execute very complicated processes across thousands of data points at once, thanks to this capability, which provides real-time insights and actions without the need for user interaction.

Deploy your own Agentic AI using papAI solution

Imagine working in a manufacturing setting where your operations are proactive, foreseeing problems and grabbing hold of opportunities before they happen. This future is attainable with papAI-powered agentic AI.

You may improve manufacturing efficiency, create sustainable development, and obtain a competitive edge by using real-time data and autonomous decision-making. Your industrial processes can quickly adjust to changes thanks to agentic AI’s real-time data analysis and action capabilities, which decrease downtime and boost throughput.

Is your company ready to explore the potential of Agentic AI in manufacturing? To find out how papAI can create a clever, customized plan for streamlining your processes, schedule a demo with our expert right now. Allow us to assist you in creating a manufacturing process that is more flexible, effective, and prepared for the future.

Agentic AI refers to an advanced form of artificial intelligence that goes beyond following commands to operating autonomously with the ability to perceive its environment, make decisions, and act independently to accomplish predefined goals.

- Basic Reflex Agents: Respond to environmental inputs based on predefined rules.

- Goal-Based Agents: Strive to accomplish specific goals by planning and evaluating various actions.

- Utility-Based Agents: Maximize a utility function to make informed decisions by weighing outcomes.

- Learning Agents: Improve performance through learning from previous experiences.

- Multi-Agent Systems: Multiple agents work cooperatively or competitively to optimize processes.

- Hierarchical Agents: Use layered structures to manage tasks in complex systems.

Agentic AI enhances decision-making by evaluating real-time data and making autonomous decisions, leading to dynamic production adaptations. It improves task adaptation by continuously learning and adjusting based on real-time data, making it especially useful for identifying inefficiencies and making proactive adjustments.

- Real-Time Production Monitoring: Agentic AI adjusts production settings based on real-time data from sensors.

- Automated Anomaly Detection: It autonomously addresses issues such as mechanical wear, preventing downtime.

- Dynamic Workflow Adjustments: AI autonomously adjusts production schedules and resource allocation based on demand fluctuations.

- Predictive Maintenance: Agentic AI forecasts equipment failures and schedules maintenance dynamically to minimize downtime.

Interested in discovering papAI?

Our AI expert team is at your disposal for any questions

How AgenticAI is Transforming Sales and Marketing Strategies

How AgenticAI is Transforming Sales and Marketing Strategies Agentic AI...

Read More“DATATEGY EARLY CAREERS PROGRAM” With Abdelmoumen ATMANI

“DATATEGY EARLY CAREERS PROGRAM” With Abdelmoumen ATMANI Hello, my name...

Read MoreIntroducing the Error Analysis Tree: A Smarter Way to Improve AI Models

Introducing the Error Analysis Tree: A Smarter Way to Improve...

Read More